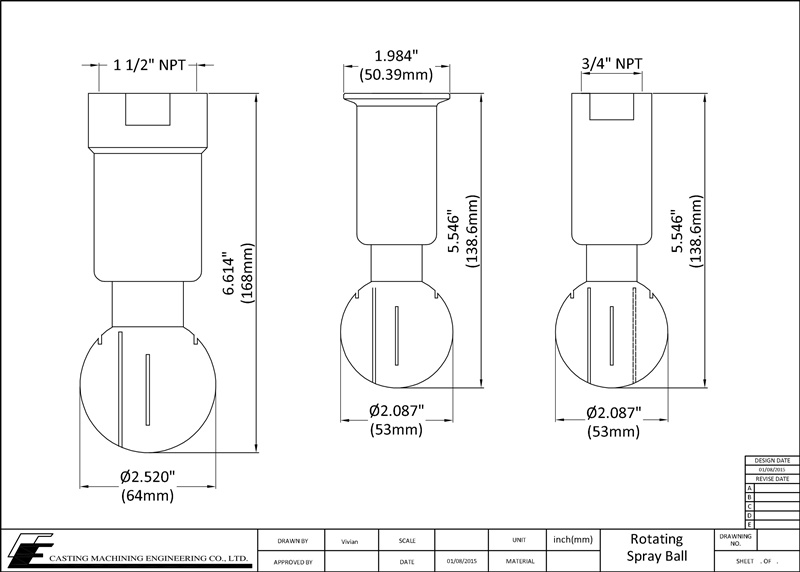

Rotating Cip Spray Ball

Rotating cip spray ball. With 3 Tri-Clamp Port x 15 TC hose connection 90 degrees. Although most CIP nozzles are used as water spray nozzles they can also be used with steam chemicals and other media. For rinsing small and medium sized vessels for example dairy chemical pharmaceutical and food industries.

In recent years the Mini spray balls have become popular which we. The Thick Walled spray balls and Mushroom balls are available in a wide range of sizes connection types materials and finishes to suit individual requirements with 31B material certificates as standard with Stainless Steel balls and other materials certificates on. Spray Balls can be drilled to target specific areas.

Similarly spray nozzles can also be used to provide additional spray patterns misting etc. The maximum pressure for custom spray balls is. A rotating spray ball allows for a cascading effect while cleaning the inside of vessels.

Applications requiring a high level of bioburden control or sterile CIP applications require equipment designed and fabricated to the ASME BPe standard. For Homebrew we have the CIP Rotating Spray Balls with Female NPT and Male NPT end connections. This effect helps to nudge any soil load and insures that all areas of a tank have been hit with cleaners and sanitizers.

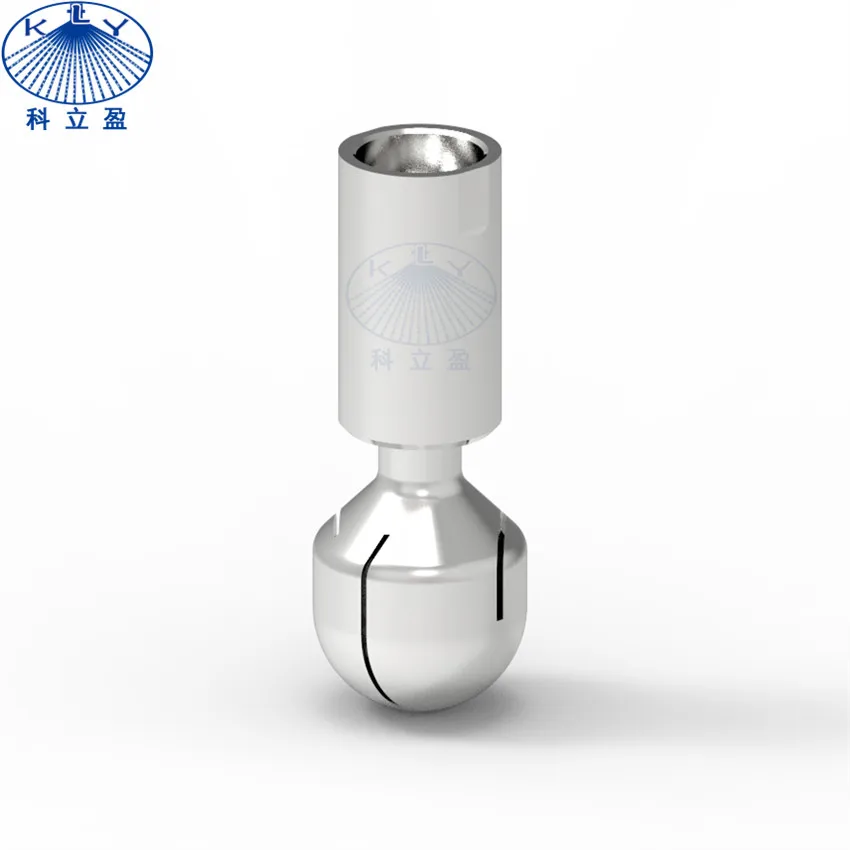

Inner and outer surfaces are full 316 stainless steel in its entirety for CIP. Rotating CIP Spray Ball 12 Tri Clover Compatible Type Connection. Tank Cleaning Spray Balls.

We stock a complete range of Spray balls. Rotary spray devices and spray balls can be considered for these applications. Similarly the mushroom balls lend themselves to applications which call for the majority of CIP to be directed back towards the spray ball inlet.

A rotating spray ball can create a. Typically a unique keyed wand with a precision drilled spray ball is.

Fixed Pin-Style Much like the rotating arm of a dish washer a rotating spray ball offers cleaning advantages over a fixed or pin-style CIP system.

Much like the rotating arm of a dish washer a rotating spray ball offers cleaning advantages over a fixed or pin-style CIP system. With 3 Tri-Clamp Port x 15 TC hose connection 90 degrees. The Thick Walled spray balls and Mushroom balls are available in a wide range of sizes connection types materials and finishes to suit individual requirements with 31B material certificates as standard with Stainless Steel balls and other materials certificates on. Suited for CIP systems. The product range includes static spray heads rotating spray balls rotating spray heads 360 degree spray nozzles and jet cleaning heads amongst other configurations. Rotary spray devices and spray balls can be considered for these applications. A rotating spray balls uses the pressure and flow of the cleaning solution to cause the ball to rotate. The Spray Ball can also be drilled to suit users specifications depending on size of vessel type of cleaning required and available flow ratepressure. A rotating spray ball can create a.

Similarly spray nozzles can also be used to provide additional spray patterns misting etc. Inner and outer surfaces are full 316 stainless steel in its entirety for CIP. With 3 Tri-Clamp Port x 15 TC hose connection 90 degrees. 25 psi is the standard design flow rate if not specified by the user. For Homebrew we have the CIP Rotating Spray Balls with Female NPT and Male NPT end connections. Designed according to the most stringent hygienic standards these provide Cleaning-in-Place CIP for vessels used in hygienic processing lines across the dairy food beverage home-personal care and biotech and pharmaceutical industries. The maximum pressure for custom spray balls is.

This comment has been removed by the author.

ReplyDelete